CAE Automotive: Process Flow

Assisting our customer step by step from sub system level to Full vehicle simulation and correlation studies…

FE Modeling

- Part Modeling

- Penetration Removal

- Connections Welds etc.

- Mesh check

- Boundary Conditions

- Numbering Naming

- Model Report

System Level simulations

- Strength Analysis of Automotive structures

- Stiffness Analysis : Bending & Torsion

- Modal Analysis/FRF

- Durability/Fatigue Studies

- Static Misuse Studies

- Multi Body Dynamics

Full Vehicle Level Simulation

- Frontal Impact / ODB

- Side Impact / Rear Impact

- Side Pole Impact Test

- Pedestrian Impact

- Impact on Steering

- Impact on Bumper

- Roof Test / Rollover Test

Introduction – Our Strength in CAE & Moldflow

Our Engineers Extensive experience in Simulations to help reduce development time, save money and make your life easier…

- Pre Process

- Solver

- Post Process

- Mold Flow Analysis

- CFD

CAE Automotive Capability Summary

Proficient in FEA, adept from subsystem to full vehicle analysis…

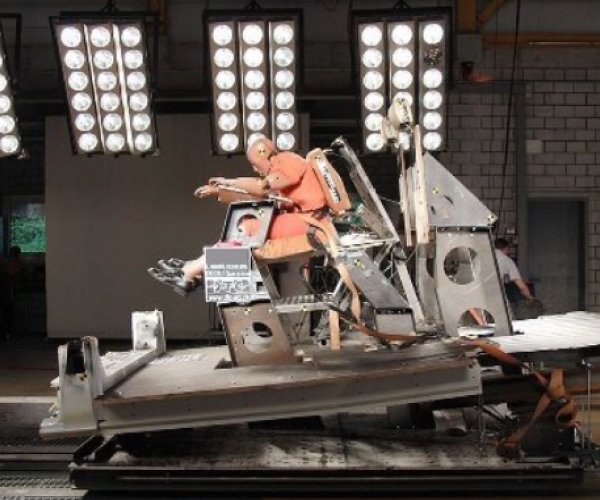

Full Vehicle Crashworthiness

- ECE94 : Frontal Impact / ODB

- ECE95 : Side Impact

- ECE32 : Rear Impact

- ECE12 : Impact on Steering

- ECE42 : Impact on Bumper

- FMVSS216 : Roof Test

- Side Pole Impact Test

- Pedestrian Impact

- Rollover Test

Vehicle Interior / Exteriors

- Modal Analysis

- Frequency Response Functions

- Stiffness & Strength Analysis

- Head Impact ECER21 / FMVSS201

- Knee Impact ECER94 / FMVSS208

- Airbag Integration / Deployment

- Thermal Load analysis

- Static Misuse

Seating System

- Modal Analysis

- FMVSS207-210 : SBA

- USNCAP : Frontal Impact

- FMVSS301 : Rear Impact

- Cargo/Occupied Cargo Impact

- FMVSS202 : Head Impact

- Knee Load Impact

- Folded Seat Impact ADR

- FMVSS225 : Child Restraints

- Mechanism Strength & Abuse

Other CAE Studies

- Durability Analysis (Structural, Vibration, Thermal Analysis)

- NVH

- CFD(Thermal, Air Intake, Fuel Tank, Water Management,Wind Noise)

- Metal Forming

- Optimization -Size, Shape, Topology

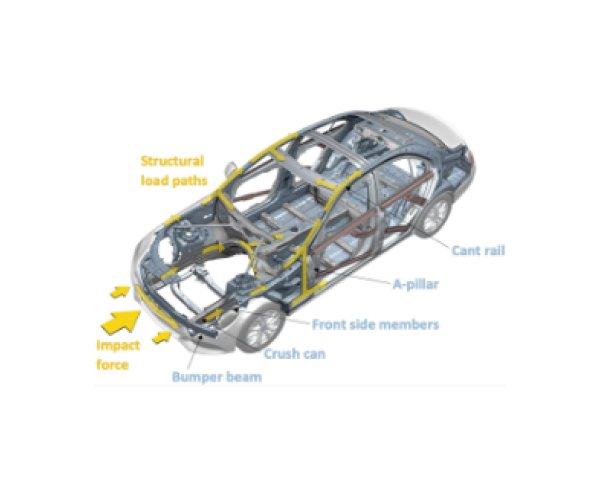

ECE94 : Offset Deformable Barrier

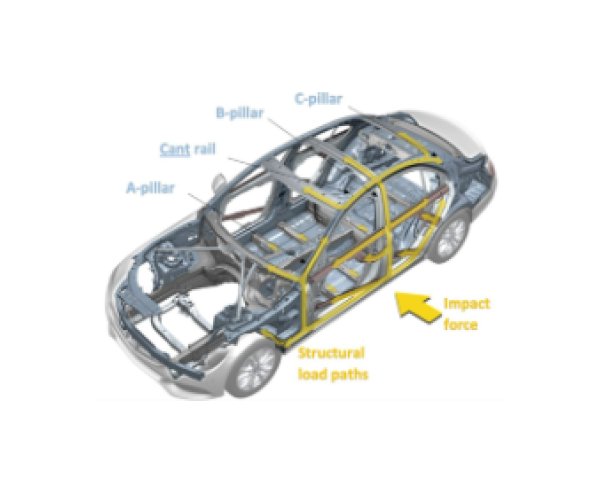

FMVSS214 : Load Path

FMVSS208: Load Path

ECE95 : Side Impact

CAE Automotive Seating System Capability

Seat Types

- Driver, Passenger

- 2/4/6 Way

- Manual & Power

- 2 Door & 4 Door

Seat System Load cases

- Modal Analysis

- FMVSS207-210 : SBA

- USNCAP : Frontal Impact

- FMVSS301 : Rear Impact

- Cargo/Occupied Cargo Impact

- FMVSS202 : Head Impact

- Knee Load Impact

- Folded Seat Impact

- ADR

- FMVSS225 : Child Restraints

- Mechanism Strength & Abuse

Seat Mechanism

- Recliner (Manual/Power )

- Tracks ( 2/4/6Way )

- Latch

- Latch Housing

- Recliner Heart

- Track Motor bridge

- Height Adjuster

- Arm Rest

- Head Rest

Seat Mechanism Load cases

- Static Forward and Rearward loading

- Abuse load cases

- Sideward/Downward/Upward loading

- 45 deg pull off test

- Combination loading

- Design Iterations to optimize

- Assembly behavior

- Maximum load carrying capacity

- Individual part study

- Validating with Physical test

1st Row Seat Side Impact

1st Row 4W Seat Frontal

1st Row 6W Rear Impact

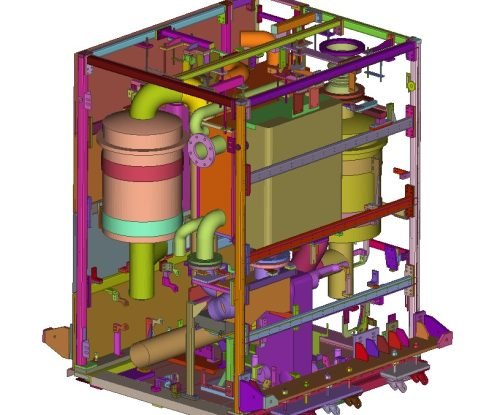

CAE Non Automotive Capability Summary

Bus Structure

Truck Cabin

Industrial Frame Unit

Locomotive Structure

Truck Front Panel

Power Storage Assembly

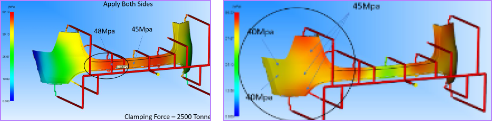

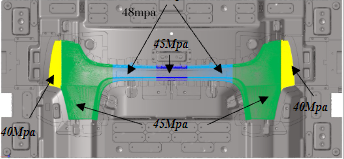

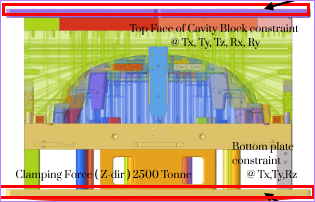

Mold FEA Capability

Our MOLD FEA team assists customers in predicting mold lifespan, identifying issues, and optimizing designs to minimize mold cost and weight…

Mold flow Pressure Load

FEA Loads

Load condition 1: The Maximum Mold flow pressure distribution considered ( Clamping Force – 2500 Tonne)

FE model Setup and Boundary

FE model Component & conditions

Component condition 1: Slides, Inserts, Lifters are considered in static position. No dynamic load considered for this analysis.

Component condition 2 : Manifold plate is a Multiple solid body without Manifold pockets