MoldFlow Capability

With MoldFlow certified professionals, we serve customers for expertise resources to identify best Mold Flow design & parameters…

CAD to Mesh Model Preparation

- Input CAD and checking

- Rheology Mesh

- Material details

- Feed system layout

- Setting up the process parameters

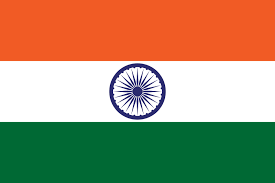

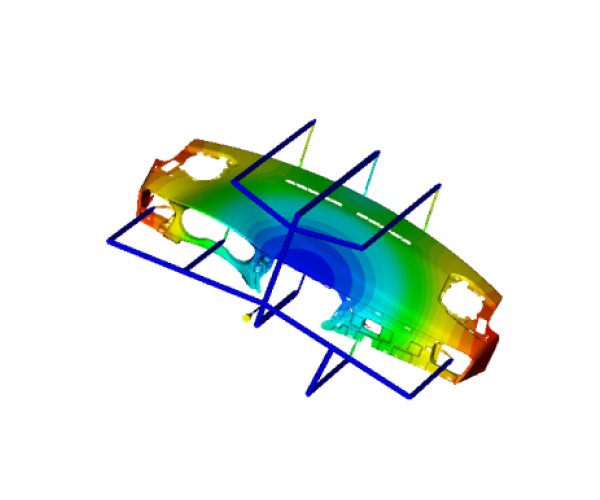

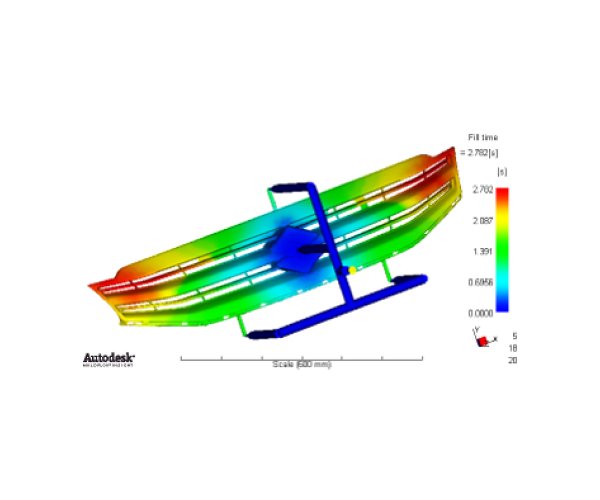

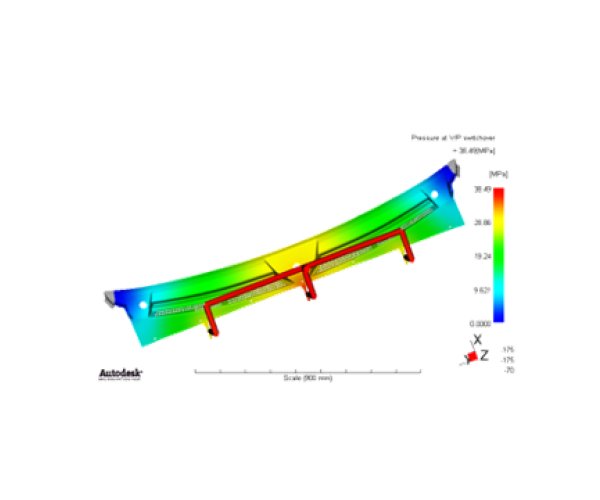

Mold Flow simulation

- Optimized Gating location with Fill and Flow study

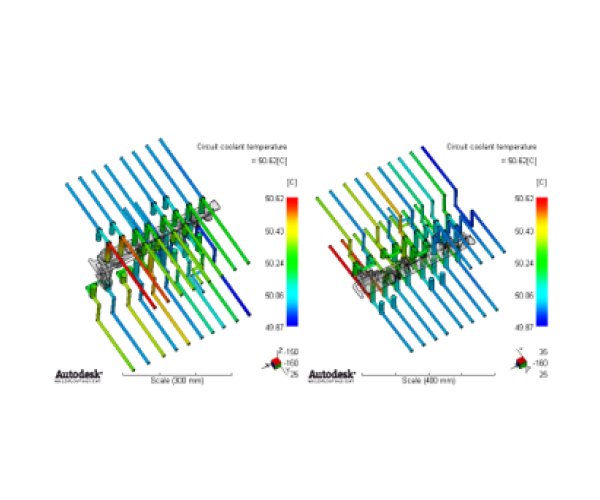

- Cool / Cool (FEM) Analysis

- Two shot molding Analysis

- Warpage & Deflection Analysis

- Weld Line & Air Trap Detection

- Injection Pressure /Temperature

- Sink Mark/Void prediction

Mold Flow Report

- Minimal number of gates / hot drops

- Placing weld line in nonvisible regions or minimizing weld lines

- Optimized process parameters to minimize cycle time without affecting part quality

- Cooling circuits efficiency validation

MoldFlow Development Study Process

Our experts optimize DFM and Material Flow analyses, prioritizing quality while minimizing costs and time…

Metal Forming Study Capability

Metal Forming simulation experts predict and resolve manufacturing issues in automotive components, ensuring smooth design transitions before production…

Thinning results

Max Failure